Thornycroft

(Natural Circulation)

Although John Isaac Thornycroft founded the Steam Carriage and Wagon Company in London during

1864, restrictive laws caused him to instead enter steam powered maritime production. Given his success

in the maritime arena, one can only speculate whether the introduction of the automobile was set back a

generation. By 1895, changes in the legislative scene encouraged Thornycroft to build a steam land

vehicle, leading to full production of steam trucks and busses in 1898. The company is still in existence,

distributing small engines based on Mitsubishi designs. At the dawn of the 20th century, however,

Thornycroft was a major force in the development of commercial motor vehicles.

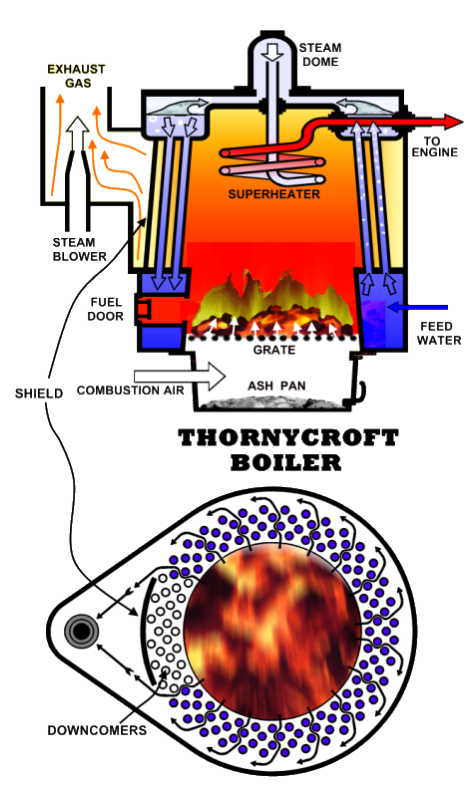

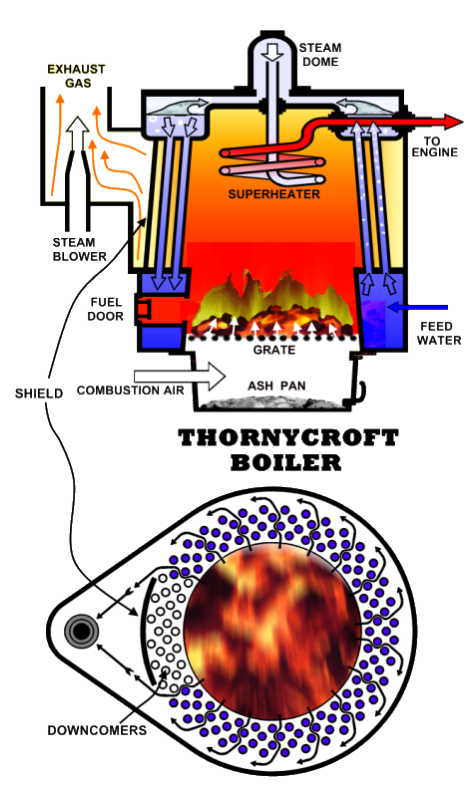

The drawing depicts a side and top view of the

Thornycroft boiler. A nearly vertical circle of

water tubes is arrayed around the firebox,

connecting annular upper and lower drums.

Combustion gasses, produced by a coal fire

resting on the grate, pass between the tubes to

the outer shell where a steam jet derived from

the engine exhaust draws the gasses into the

exhaust stack and propels them out of the boiler.

Supply of air to the burner is termed ‘draft’.

The term induced draft is used when gas flow

results from a mechanism forcing the exhaust

out of the boiler with the resulting partial

vacuum drawing in new air. Forced draft

describes mechanisms which force air into the

burner, such as the fan in the Doble burner.

Induced draft is preferred for solid fuel burners

because the exhaust blower maintains the

firebox pressure slightly below the atmosphere

which causes air to rush in rather than flames

rushing out whenever the door is opened to add

fuel.

The Thornycroft boiler circulates naturally,

differences in water density causing the water to

descend in the downcomer tubes and rise in the

generator tubes. Downcomers are commonly of

larger diameter than generator tubes and

shielded from the boilers heat; this case is

unusual in that the generator and downcomer

tubes are identically sized. A shield between the

firebox and exhaust stack prevents the flow of

hot combustion gases between the downcomer

tubes which reduces the heat they absorb and

allows the water inside to descend.