Doble Water Tube Boiler

(monotube)

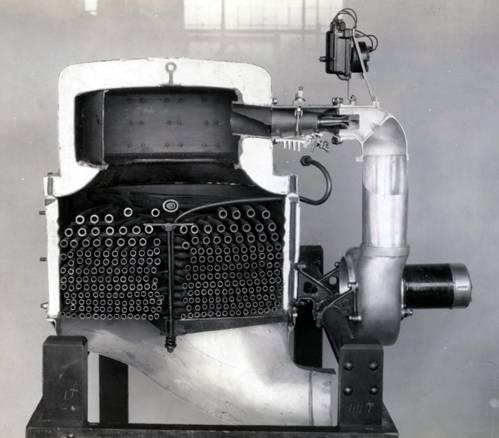

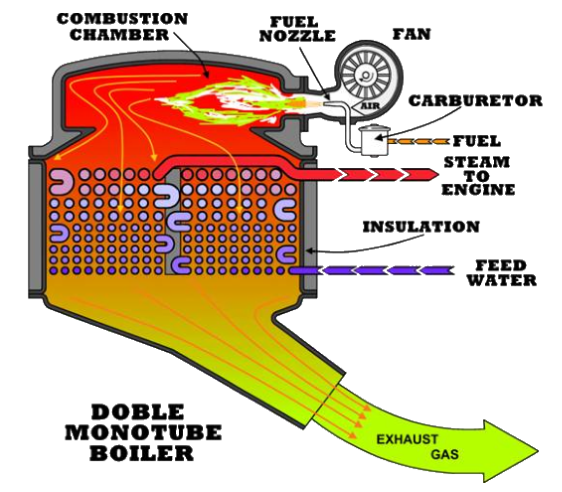

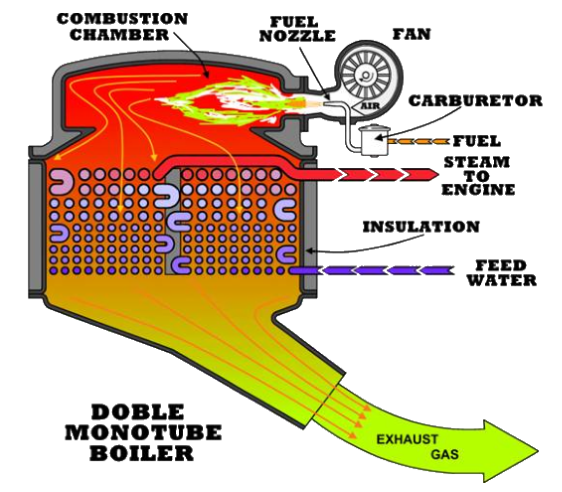

Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam

vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and

igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler

reached operating temperature and pressure in much less time than the Stanley. Doble images

The Doble is a once-through boiler, water entering one end and heat applied until emerging from the

other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop,

extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is

only one tube for the water to pass through rather than a number of parallel tubes.

*

The small water volume provides

little reserve power in excess of

maximum steady state output.

*

Superheating in a tube only starts

above the water level; minor level

fluctuation changes the length of the

portions generating and

superheating steam, making

accurate control difficult.

*

The peak firing rate is limited by

DNB and a circulation ratio of 1.

Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for

generations and only relatively recently are we seeing a shift.

Doble Water Tube Boiler

(monotube)

Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam

vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and

igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler

reached operating temperature and pressure in much less time than the Stanley. Doble images

The Doble is a once-through boiler, water entering one end and heat applied until emerging from the

other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop,

extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is

only one tube for the water to pass through rather than a number of parallel tubes.

*

The small water volume provides

little reserve power in excess of

maximum steady state output.

*

Superheating in a tube only starts

above the water level; minor level

fluctuation changes the length of the

portions generating and

superheating steam, making

accurate control difficult.

*

The peak firing rate is limited by

DNB and a circulation ratio of 1.

Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for

generations and only relatively recently are we seeing a shift.

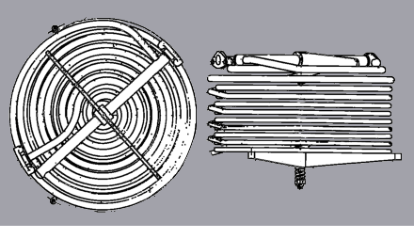

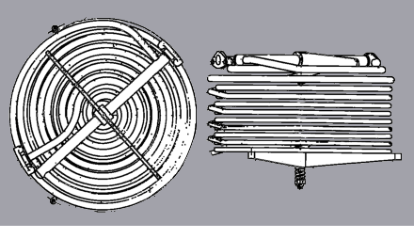

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube

windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a

‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next

‘pancake’ and then spirals outwards. See image of Doble ‘pancake’ coil stack below.

The illustrations show the monotube

growing progressively larger from

entrance to exit; this enlargement serving

to check velocity and resistance buildup as

heating causes the water to expand.

Because the boiler is also drumless (see

what we mean about endless classifications

in steam technology?), it is very safe, the

stored energy in the small volume of water

presenting minimal hazard in the event of a

tube failure. Compared to a fire tube

boiler, there is little water or metal mass to

be heated, allowing the boiler to reach

operating pressure rapidly. The monotube

has its tradeoffs:

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube

windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a

‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next

‘pancake’ and then spirals outwards. See image of Doble ‘pancake’ coil stack below.

The illustrations show the monotube

growing progressively larger from

entrance to exit; this enlargement serving

to check velocity and resistance buildup as

heating causes the water to expand.

Because the boiler is also drumless (see

what we mean about endless classifications

in steam technology?), it is very safe, the

stored energy in the small volume of water

presenting minimal hazard in the event of a

tube failure. Compared to a fire tube

boiler, there is little water or metal mass to

be heated, allowing the boiler to reach

operating pressure rapidly. The monotube

has its tradeoffs:

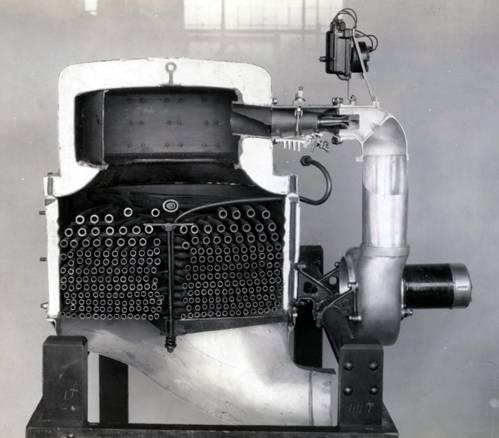

Doble Water Tube Boiler

(monotube)

Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam

vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and

igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler

reached operating temperature and pressure in much less time than the Stanley. Doble images

The Doble is a once-through boiler, water entering one end and heat applied until emerging from the

other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop,

extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is

only one tube for the water to pass through rather than a number of parallel tubes.

*

The small water volume provides

little reserve power in excess of

maximum steady state output.

*

Superheating in a tube only starts

above the water level; minor level

fluctuation changes the length of the

portions generating and

superheating steam, making

accurate control difficult.

*

The peak firing rate is limited by

DNB and a circulation ratio of 1.

Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for

generations and only relatively recently are we seeing a shift.

Doble Water Tube Boiler

(monotube)

Doble Steam Motors automobiles, built from 1924-1931, are considered by many to be the finest steam

vehicles ever produced, with the boiler figuring significantly in this evaluation. An electric fan and

igniter made the burner faster and easier to start and the small volume of fluid in the water tube boiler

reached operating temperature and pressure in much less time than the Stanley. Doble images

The Doble is a once-through boiler, water entering one end and heat applied until emerging from the

other as steam in contrast to recirculating boilers which cycle water endlessly through a heating loop,

extracting only that portion converted to steam. The Doble is also a monotube boiler, meaning there is

only one tube for the water to pass through rather than a number of parallel tubes.

*

The small water volume provides

little reserve power in excess of

maximum steady state output.

*

Superheating in a tube only starts

above the water level; minor level

fluctuation changes the length of the

portions generating and

superheating steam, making

accurate control difficult.

*

The peak firing rate is limited by

DNB and a circulation ratio of 1.

Notwithstanding the above tradeoffs, monotube boilers have been the favored steam car boiler for

generations and only relatively recently are we seeing a shift.

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube

windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a

‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next

‘pancake’ and then spirals outwards. See image of Doble ‘pancake’ coil stack below.

The illustrations show the monotube

growing progressively larger from

entrance to exit; this enlargement serving

to check velocity and resistance buildup as

heating causes the water to expand.

Because the boiler is also drumless (see

what we mean about endless classifications

in steam technology?), it is very safe, the

stored energy in the small volume of water

presenting minimal hazard in the event of a

tube failure. Compared to a fire tube

boiler, there is little water or metal mass to

be heated, allowing the boiler to reach

operating pressure rapidly. The monotube

has its tradeoffs:

The Doble monotube is composed of a number of helical ‘pancake’ coils, so named because the tube

windings comprise flat discs stacked upon one another and connected end-to-end. Water entering a

‘pancake’ from the outside spirals inwards until reaching center, moves upwards to the next

‘pancake’ and then spirals outwards. See image of Doble ‘pancake’ coil stack below.

The illustrations show the monotube

growing progressively larger from

entrance to exit; this enlargement serving

to check velocity and resistance buildup as

heating causes the water to expand.

Because the boiler is also drumless (see

what we mean about endless classifications

in steam technology?), it is very safe, the

stored energy in the small volume of water

presenting minimal hazard in the event of a

tube failure. Compared to a fire tube

boiler, there is little water or metal mass to

be heated, allowing the boiler to reach

operating pressure rapidly. The monotube

has its tradeoffs: