Physicists classify thermodynamic processes as reversible and irreversible, reversible processes are

desirable and non-reversible often reduces efficiency. The expander demonstrates a reversible process,

steam expanding in the cylinder gives up pressure and temperature to produce work at the crankshaft;

by applying power to the crankshaft the process is reversed and steam is compressed to higher

pressure and temperature. Condensers epitomize nonreversible processes; heat easily flows from the

hot steam to the cool air but never from cool air to hot steam. Basic power cycles are models

illustrating principles and allowing calculations of performance and efficiency. In the real word,

friction and imperfect insulation cause systems to be less efficient than the ideal cycle; sometimes the

equipment can be modified to advantageously exchange heat within the system in ways the basic model

does not describe, improving efficiency. The boiler feed heater is a simple example of such an

exchange, a portion of the heat leaving the expander in the form of exhaust steam is transferred to the

cooler feed water (condensate) entering the boiler; this pre-heating causes less fuel to be burned in the

boiler, improving overall efficiency. Large steam power plants are highly efficient, not so much

because they employ the Rankine cycle, but because they modify the cycle to minimize losses. Small

Diesels often match large steam plant efficiency because the basic Diesel cycle is more efficient (there is

no energy tied up in the heat of vaporization) but Diesels do not lend themselves to producing the same

large outputs as steam turbines.

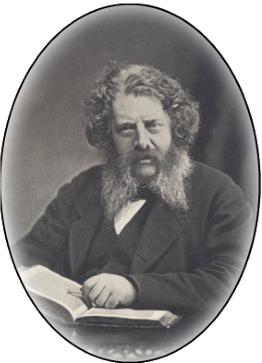

The Rankine cycle (steam cycle) is named after Scottish civil

engineer, physicist and mathematician William John

Macquorn Rankine (5 July 1820 – 24 December 1872).

Roughly contemporaneously with Rudolf Clausius and

William Thomson (First Lord Kelvin and namesake of the

Kelvin temperature scale) he established many of the basics of

thermodynamics. Among his achievements were discovering

relationships between the temperature, pressure and density

of gasses and the latent heat of vaporization. He outlined

practical applications of the law of conservation of energy and

eventually developed a description of dynamic processes as

related to energy and its transformations. The Rankine scale

of temperature is named after him.

Engineers divide steam hardware into countless classifications and sub-classifications and sub-sub-

classifications and....you get the point; the extreme diversity often makes classification very difficult.

Nevertheless, let us look at a few basic classifications to get a feel for steam generators. The most basic

divide is between fire-tube and water-tube (although some difficult souls have built boilers with both

elements to frustrate attempts to bring order). Both types of steam generator transfer heat from

combustion gasses to water through tube walls which keep the gasses and water separate. Fire-tube

boilers pass hot gasses (fire) through the tube interior, heating water passing over the exterior; water-

tubes (naturally) do the opposite, water passing through the interior of a tube heated by hot gasses

passing over the exterior.

The answer to the question “How does boiling occur?” seems obvious, “Add heat”, but is more involved

when one resolves to commit engineering. Boiling occurs when steam bubbles form upon microscopic

deformations in the tube wall called nucleation sites. Bubbles leaving the nucleation site carry heat

energy away from the tube which limits temperature build up and keeps the metal safe from burnout.

Of course, the steam bubbles eventually end up powering the engine.

Excess heat flux leads to a departure from nucleate boiling (DNB); which is a fancy way of saying the

small bubbles given off by the tube wall are replaced by larger, more permanent, steam formations or

films. Steam films are good insulators and trap heat in the tube wall, which raises metal temperatures

and leads to burnout. Pressure and temperature affect DNB at a given firing rate, increased pressure

leads to higher saturation temperatures, delaying boiling onset. Meanwhile, rising flow velocity

permits harder firing as the resulting turbulence scours nucleation sites clean of larger steam bubbles

and films, restoring steam bubble creation and heat transfer to the water.

Since steam leaves a boiler at one point, and enters at another, there is obviously a flow through the

boiler. Two basic types of flow are possible, either once-through or recirculating. A childhood

playground analogy might be in order. The slide is a once-through device; a child enters at one end and

exits the other. The merry-go-round is a recirculating device, the child boards and makes an

undetermined number of trips around before debarking. The circulation rate is defined as the weight of

water travelling in boiler divided by the weight of the feed. In playground terms, the slide has a

circulation ratio of 1 to 1, the weight of children on the slide is equal to the weight entering and leaving.

The circulation ratio of the merry-go-round depends on how long the children ride, if each child makes

ten revolutions before giving another a turn, the circulation ratio will be 10 to 1.

Recirculating boilers come in two varieties, natural and forced. Natural circulation occurs when flow is

produced by density differences between hotter water in generating tubes and the colder water in the

downcomers (a tube that carries water downwards in natural circulation boilers!). Natural circulation is

not limited to boilers, occurring in ocean currents, winds, chimneys and so on. Forced circulation involves

a pump to circulate the fluid.

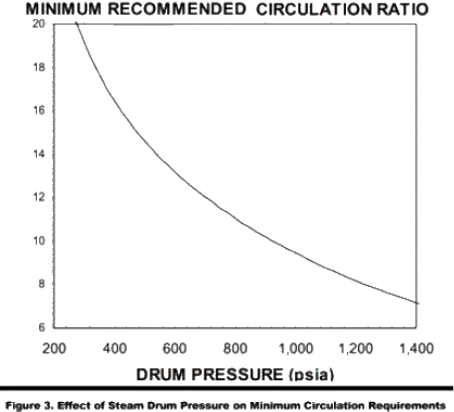

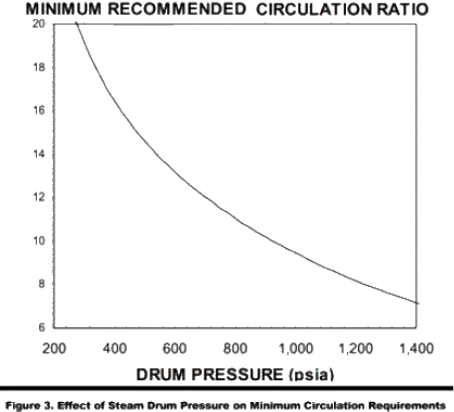

This graph, taken from the Jansen Combustion and

Boiler technologies website, illustrates their view of

the desired relationship between pressure and

circulation rate. These ratios are a minimum value

and faster circulation will insure against operational

damage.

GENERATION, continued

GENERATION, continued

GENERATION, continued

GENERATION, continued