Surface condensers work indirectly, steam gives up heat to one surface of the condenser gives while a

coolant such as water or air absorbs that heat from the other. “Direct contact condensers” have no

intermediary surfaces; the steam and coolant (usually water) directly contact each other although a heat

exchanger may eventually cool the resulting mixture.

Direct Contact Condensers

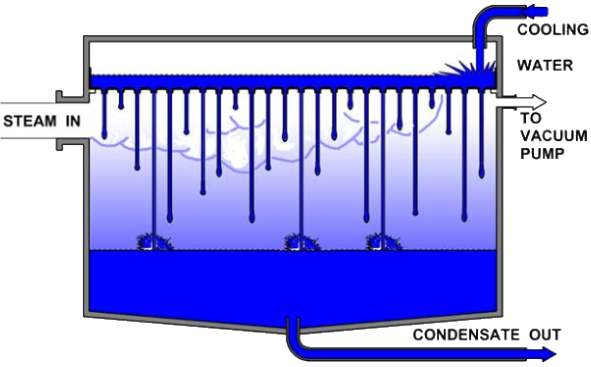

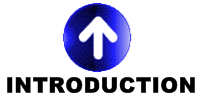

Jet condensers are direct contact

condensers which spray a jet of

cooling water into the steam to be

condensed. One of the earliest types

(to right) is little more than a

perforated horizontal pan inside the

upper portion of a metal box.

Pumping water into the pan causes a

shower, condensing steam admitted

to the space below. This

condensation causes a vacuum which

is maintained by a vacuum pump

that removes air and other non-

condensable gasses liberated from

the steam, a water pump removes the

condensate against the resulting

vacuum

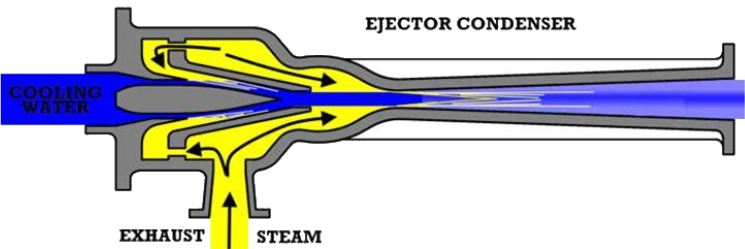

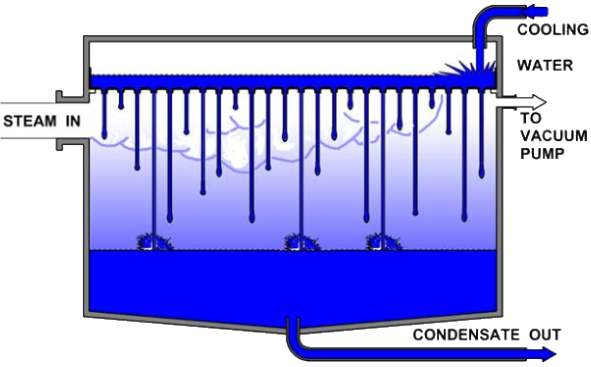

Possibly the most common jet condenser is the ejector condenser, ejectors being a type of “jet pump”. A

nozzle accelerates a moving stream of water, directing it through an enclosed cavity through which the

exhaust steam is admitted. The moving water entraps the steam, and any resident air, carrying them out

the discharge nozzle. Ejector condensers are compact and need no air or vacuum pump, the fluid flow

itself removing entrained air. Ejector condensers may reduce engine output because the engine must

supply the power to pump the fluid flow.

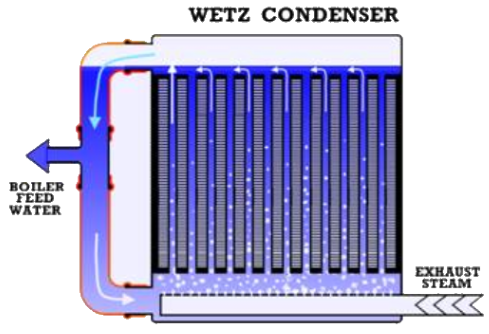

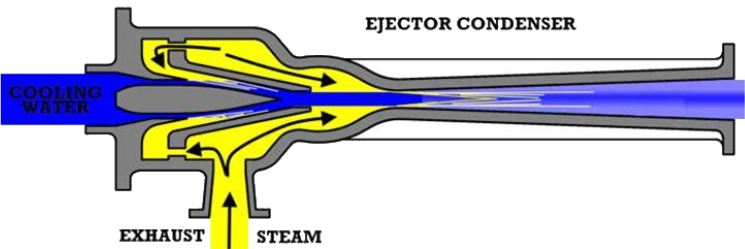

SACA member John Wetz took the unusual

step of converting an automotive radiator

into a direct contact, rather than a surface

condenser. While his radiator is not suitable

for vacuum condensing, it is affordable and

apparently effective. A hose connecting the

upper and lower radiator manifolds

facilitates circulation by serving as a

downcomer, a tee in the hose supplies water

to the boiler feed pump. Steam is admitted

evenly across the lower manifold from within

a perforated pipe. The steam bubbles rise

through the water columns in the finned

radiator tubes and condense on contact with

the surrounding water. The cooled

condensate spills over into the upper

manifold into the downcomer hose, some of

the condensate being drawn back to the

boiler by the feed water pump and the rest

free to sink to the lower manifold and

establish a natural circulation.