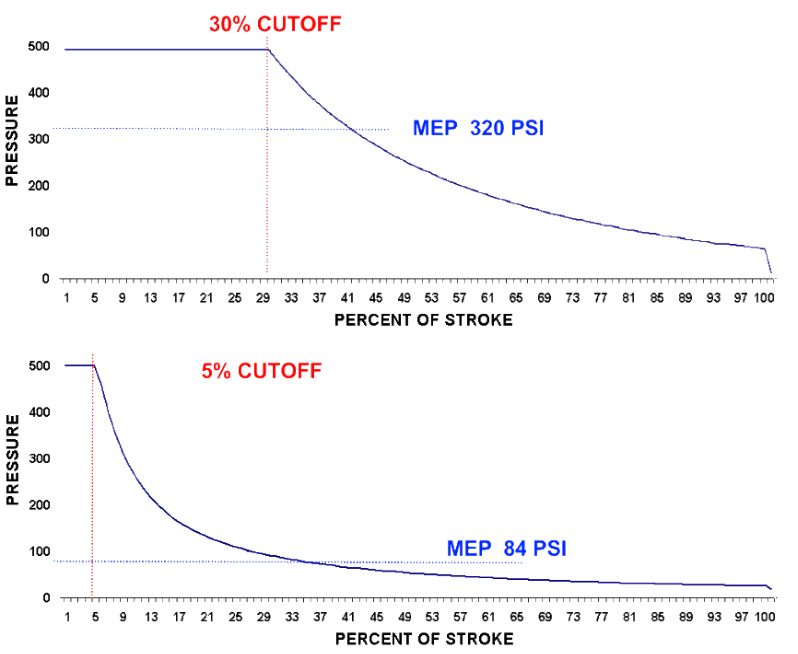

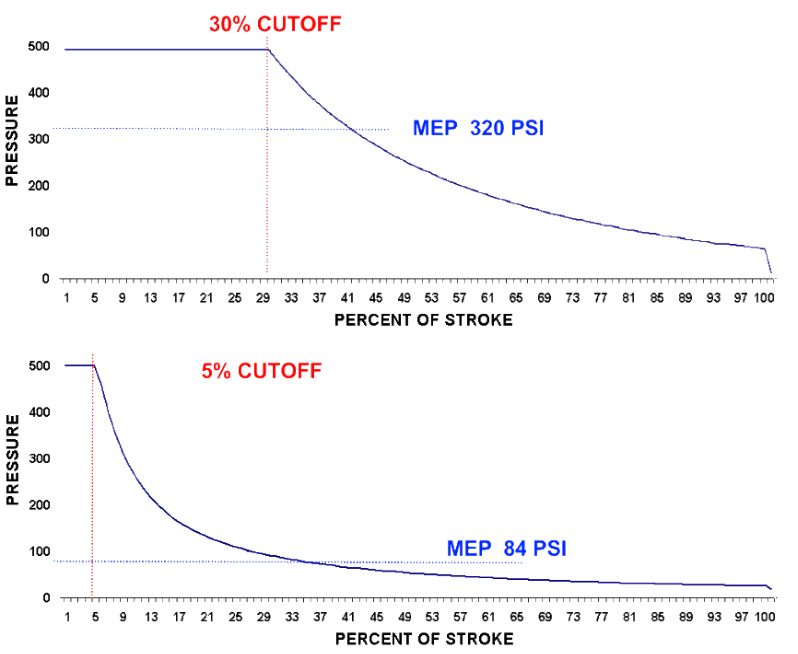

Steam enters at 500 psi in both cases, with a cutoff of 30% in the upper graph with a cut off at 30%

and 5% in the lower. The curves represent the pressure as the piston travels down the cylinder,

with the area beneath the curves being equal to the work developed. The average pressure for the

stroke in the upper case is 320 psi and 84 psi in the lower. We can say the Mean Effective Pressures

were 320 psi and 84 psi, respectively, and estimate that in the second case the engine is about

one-fourth as powerful according to PLAN.

Because 19th century steam engine valves

usually admitted and exhausted steam

through the same port, the hot incoming

steam traversed a passage just travelled by

the outgoing cool exhaust, cooling the

incoming steam and causing premature

condensation, robbing efficiency. Breaking

the expansion into smaller steps reduces

the temperature drop in each cylinder, less

heat is transferred to the engine parts, leading

to a further efficiency gain. “Compounding” is

the process of breaking expansion into smaller

steps and to this day is the basis for our most

efficient and advanced steam and gas turbines.

Each expanding element is now termed a “stage”,

though at one time it was called an “expansion”;

thus an engine that expands the steam three

times is a triple expansion engine or a three-stage

expander. An expander with just one stage is

a “simple” expander and two stages a compound.

PLAN is an acronym for a formula to calculate theoretical horsepower in a single cylinder:

Pressure

(MEP, in psi)

Length

(of stroke, in feet)

Area

(cylinder inside diameter, square inches)

Number

(of revolutions, per minute)

Horsepower = (P x L x A x N) / 33,000

We can verify this equation by comparing it with basic terms in mechanics, the first being that 1

Horsepower = 33,000 foot-pounds per minute.

*

The Pressure (MEP) multiplied by the piston area determines the average force on the

piston in pounds.

*

The distance the piston travels in feet multiplied by the average force in pounds yields the

work produced in foot-pounds.

*

The work produced times the number of RPM calculates the power developed per minute

in foot-pounds per minute.

*

Dividing the power by 33,000 converts the work from foot-pounds per minute to

horsepower.

The area beneath the upper curve looks relatively ‘fat’ compared the relatively, ‘skinny’ lower

curve; engineers study such curves to determine both potential power and efficiency. Fat curves,

with their higher MEP, produce more horsepower for their size but do so by wastefully disposing

pressurized steam from the exhaust. Skinny curves indicate the steam is fully expanded and

operating efficiency but also indicates lower overall power output. Mechanisms called valve gears

regulate how early or late in the stroke cutoff occurs, adjustable valve gears can provide either

skinny or fat curves as needed.

Short cutoff implies the valve will be open briefly, which in turn requires high valve speed to

complete the cycle from closed to open and closed again in a short time; such fast operation is

technically demanding as extra stress, friction and wear must be managed. Overall efficiency

improves with the adoption of higher pressures and temperatures, if the engine can expand the

steam fully. The inability to use short cutoff practically limits useable pressures and efficiency. In

the 19th century it became feasible to generate higher steam pressures, but remained a challenge to

build valves able to use the steam effectively. Suppose we desire a cutoff of 10%, but can only

practically build engines of 30%, it soon becomes apparent that the steam leaving the cylinder still

possesses enough pressure to operate another cylinder. By expanding transferring this exhaust

steam to a larger cylinder and cutting it off at 30% cutoff, transferring the steam to a larger

cylinder and expanding again with 30% cutoff, we achieve a higher overall expansion ratio than

our desired 10% cutoff. Rising pressures and temperatures led to the use of three and even four

cylinders.

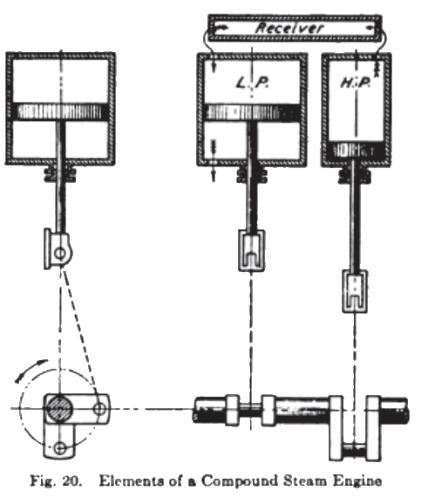

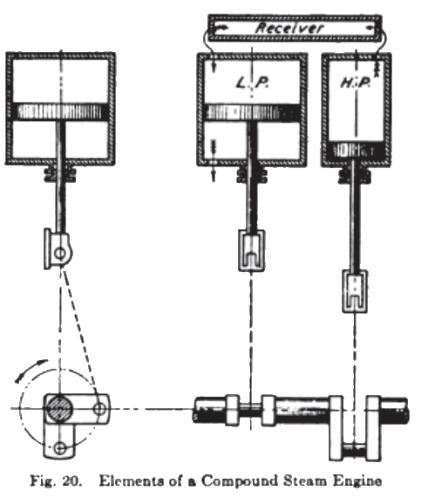

The above drawing illustrates the basic components of a compound engine. The smaller high

pressure (HP) cylinder, to right, partially expands steam which exhausts to a receiver. The receiver

levels out variations in pressure and supplies steam to the larger low-pressure cylinder (LP) which

expands the steam further. By adding stages, one can accommodate higher steam pressures and

shorter cutoffs.

“Mean Effective Pressure”, (MEP), the average steam pressure during an engine stroke, is proportional

to the power developed and generally inversely proportional to efficiency.

These graphs reflect the same engine running with the same steam pressure, but with using differing

cutoff:

The above drawing illustrates the basic components of a compound engine. The smaller high

pressure (HP) cylinder, to right, partially expands steam which exhausts to a receiver. The receiver

levels out variations in pressure and supplies steam to the larger low-pressure cylinder (LP) which

expands the steam further. By adding stages, one can accommodate higher steam pressures and

shorter cutoffs.

“Mean Effective Pressure”, (MEP), the average steam pressure during an engine stroke, is proportional

to the power developed and generally inversely proportional to efficiency.

These graphs reflect the same engine running with the same steam pressure, but with using differing

cutoff:

EXPANSION, page 2

EXPANSION, page 2

The above drawing illustrates the basic components of a compound engine. The smaller high

pressure (HP) cylinder, to right, partially expands steam which exhausts to a receiver. The receiver

levels out variations in pressure and supplies steam to the larger low-pressure cylinder (LP) which

expands the steam further. By adding stages, one can accommodate higher steam pressures and

shorter cutoffs.

“Mean Effective Pressure”, (MEP), the average steam pressure during an engine stroke, is proportional

to the power developed and generally inversely proportional to efficiency.

These graphs reflect the same engine running with the same steam pressure, but with using differing

cutoff:

The above drawing illustrates the basic components of a compound engine. The smaller high

pressure (HP) cylinder, to right, partially expands steam which exhausts to a receiver. The receiver

levels out variations in pressure and supplies steam to the larger low-pressure cylinder (LP) which

expands the steam further. By adding stages, one can accommodate higher steam pressures and

shorter cutoffs.

“Mean Effective Pressure”, (MEP), the average steam pressure during an engine stroke, is proportional

to the power developed and generally inversely proportional to efficiency.

These graphs reflect the same engine running with the same steam pressure, but with using differing

cutoff:

EXPANSION, page 2

EXPANSION, page 2